- Wide input Voltage Operating Range from 65 V to 165 VDC.

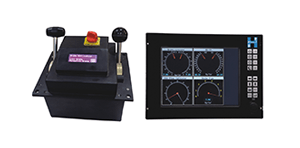

- High Resolution 10.4” 1024 x 768 High Resolution Display with 16.7M color for best clarity

- User adjustable LED backlight brightness and contrast settings with dedicated function keys.

- Spare keys provided for customer definable functions.

- Modular keyboard design for easy and intuitive navigation of various display screens.

Railways

Industrial

Electronic Safety Protection Device for Railways

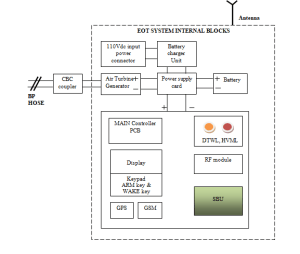

- The HIRECT EoT unit is placed in a rugged enclosure with adjustable mounting bracket. The end-of-train devices (EOTs) provides information about brake pipe pressure measured at the rear of the train, and various status conditions.

- The EOT also processes and responds to HOT Instruction, for example emergency brake commands, train passages acknowledgement command.

- The air supply from the BP will be given to the EoT unit. The air Generator inside EoT unit will convert the pneumatic energy into DC supply, which will power the unit.

- EoT unit reports its current location to the HoT unit in regular interval. The radio unit used in both HoT and EoT are designed as per AAR S9152 V2.1 standard

- Equipped with Air turbine Generator and Battery

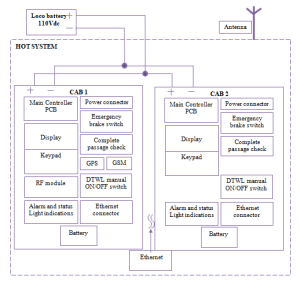

- Hirect EoTT system offers two HoT units for both cabs and both units will work in master-slave mode.

- HoT Units are intended to be fitted in both cabs of the locomotive with the display units for proper monitoring by the LP and ALP. Locomotive number shall be the unique identifier for the HoT device

- HoT Units are intended to be fitted in both cabs of the locomotive with the display units for proper monitoring by the LP and ALP. Locomotive number shall be the unique identifier for the HoT device

- Data storage facility with more than 30 days in FIFO basis is provided.

- Modular Design

- Electronic Controlled pneumatic Brake controller consists of electronic charging Discharging Valve for Brake Pipe and Brake cylinder. The panel has additional Fully Mechanically operated valve for failsafe operation at the time of Electronic Failure. The mechanically operated valves can operate brake system at the time of power failure and fully complied with UIC540

- Electronic Brake Handle (both Loco Brake SA9 and Formation Brake handle A9). 2 x 20 based LCD display is available for showing different fault status and mode of operation etc

- Auxiliary Pneumatic Panel for Controlling Feed Pipe, Pantograph, VCB, Unloader, Sander etc

- Electronic Vigilance Control Computer

- Soft PLC based Computer for controlling overall brake system. It consists of multiple Digital and Analog 10 Cards with ARM Processor based cards. Communication Protocols used are CAN for backbone real-time communication, Ethernet for Diagnostic Data, RS485 and RS232 for additional communication.

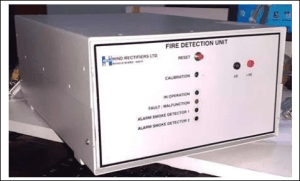

- FDU is used in SB-2 Panel of 3-Phase AC Locomotives. This Fire detection Unit is used to sense any smoke present in the Locomotive during its operation and notify the driver about the same.

- FDU indicates the driver about any fault such as rupture, blockage, and leakage in its air suction system Via the LED Indicator display.

- The air is captured by suction system which is present in the locomotive. During its normal operation, if smoke is present in the Locomotive, the FDU will sense the smoke and generate the signal and send it to VCU. This message will be transmitted to DDU. DDU will display the fault “Fire Detection” at Subsystem 15, along with title “FIRE IN MACHINE ROOM”

- The Fire Detection Unit (FDU), which is installed in a metal case, consists of the following materials:

- Smoke detection unit, 2 smoke detectors are installed inside the case

- Visual indications for operations, fault/malfunction monitoring with alarm

- Input sense Voltage: 240 VAC ±10%, 50-60Hz

- Adjustment of input values: Setting Range available from 0 to 240 V, Where Un = 200V

- Auxiliary Supply: Nominal : 48 VDC Operating range (36 V to 68 VDC)

- Supply Rated Burden: Supply Rated burden 3W

- Maximum Value of Harmonics on Input: Less than 5%