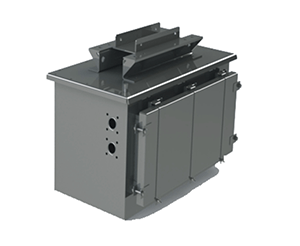

- Panel with surge arrester, current sensor, contractor, capacitor etc.

- Equipped with all necessary protection device for locomotive auxiliary equipment

- Side window for inspection and easy maintenance

- Marking of each wire for identification

- 110VDC

Railways

Industrial

Railways

- Equipped with all necessary protection device for locomotive auxiliary equipment

- Provide interface between control electronics and other devices

- Equipped with switchgear for battery charger, DC-DC converter, earthing fault, fire detection etc.

- Easy front access to all the devices fitted in the panel

- Front side glass window for inspection

- Equipped with all necessary protection device for locomotive auxiliary equipment

- Provide interface between control electronics and other devices

- Equipped with switchgear for battery charger, DC-DC converter, earthing fault, fire detection etc.

- Easy front access to all the devices fitted in the panel

- Front side glass window for inspection

- Equipped with all necessary protection device for locomotive auxiliary equipment

- Equipped with switchgear for Machine Room Blower, Compressor, Crew Fan, Cab Heater, earthing fault.

- Easy front access to all the devices fitted in the panel

- Front side glass window for inspection and easy maintenance.

- 110VDC

- 415VAC,50Hz.

- Equipped with all necessary protection device for locomotive auxiliary equipment

- Equipped with switchgear for Machine Room Blower, Compressor, Crew Fan, Cab Heater, earthing fault.

- Easy front access to all the devices fitted in the panel

- Front side glass window for inspection and easy maintenance

- 110VDC

- For main distribution panel between driver desk controls units and auxiliary control cubicle ,wago connector and circular connector used.

- 110VAC

- 110VDC

- 48VDC

- 24VDC

- EOG AC Coaches/Power car/Pantry car requires 750V/415V step down transformer for coach power supply.

- Their capacity requirement is 60 kVA and these transformers are mounted underslung.

- Nominal Input:60 kVA

- Voltage:3 phase , 4 Wire, 750 V ± 5% (line to line), 50 Hz ±3%, THD < 10%

- Output: 415 VAC

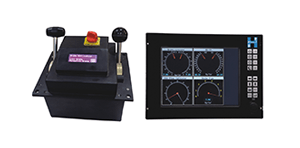

- Electronic Controlled pneumatic Brake controller consists of electronic charging Discharging Valve for Brake Pipe and Brake cylinder. The panel has additional Fully Mechanically operated valve for failsafe operation at the time of Electronic Failure. The mechanically operated valves can operate brake system at the time of power failure and fully complied with UIC540

- Electronic Brake Handle (both Loco Brake SA9 and Formation Brake handle A9). 2 x 20 based LCD display is available for showing different fault status and mode of operation etc

- Auxiliary Pneumatic Panel for Controlling Feed Pipe, Pantograph, VCB, Unloader, Sander etc

- Electronic Vigilance Control Computer

- Soft PLC based Computer for controlling overall brake system. It consists of multiple Digital and Analog 10 Cards with ARM Processor based cards. Communication Protocols used are CAN for backbone real-time communication, Ethernet for Diagnostic Data, RS485 and RS232 for additional communication.

- Connection: Single

- Input Voltage : 1222VAC

- Output Current : 3300 ADC

- Output Voltage : 750 VDC

- Power : 5400 kVA

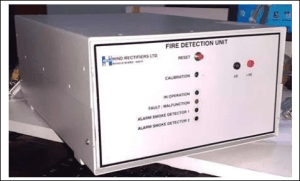

- FDU is used in SB-2 Panel of 3-Phase AC Locomotives. This Fire detection Unit is used to sense any smoke present in the Locomotive during its operation and notify the driver about the same.

- FDU indicates the driver about any fault such as rupture, blockage, and leakage in its air suction system Via the LED Indicator display.

- The air is captured by suction system which is present in the locomotive. During its normal operation, if smoke is present in the Locomotive, the FDU will sense the smoke and generate the signal and send it to VCU. This message will be transmitted to DDU. DDU will display the fault “Fire Detection” at Subsystem 15, along with title “FIRE IN MACHINE ROOM”

- The Fire Detection Unit (FDU), which is installed in a metal case, consists of the following materials:

- Smoke detection unit, 2 smoke detectors are installed inside the case

- Visual indications for operations, fault/malfunction monitoring with alarm

- Wide Band Contactors are used. Compatible with Head on Generation rolling stock.

- Compact in Size and stainless steel is used for structure.

- 750 VAC, 3 Phase, 3Wire System, 50 Hz

- 110 VDC

-

- 750VAC, 3 Phase, 3Wire system, 50 Hz

- Wide Band Contactors are used. Compatible with End on Generation rolling stock.

- 750 VAC, 3 Phase, 4/3Wire System, 50 Hz

- 110 VDC

-

- 415 VAC, 3 Phase, 4 Wire System, 50 Hz

- 240 VAC, 1 Phase, 50 Hz